EDIBLE OIL EXTRACTION TIMELINE fr

A journey through oil extraction key milestones

This edible oil extraction timeline shows how methods to make oils from seeds and fruits has developed and improved over thousands of years. It starts with the ancient way of making olive oil around 5000 BC and continues through the centuries. It highlights the creativity and progress in producing essential oils that are now so important in our food and other products.

5,000 BCOlive oil produced

The first olive oil producer was primitive man who employed a stone mortar to squeeze fallen olives and noticed that oil was released (ca. 5000 BC). Ancient civilizations of the Middle East and the littoral territories of the Mediterranean basin have left clear evidence of flourishing olive cultivation and oil production.

2,000 BCSesame oil produced

Evidence of this can be seen from the charred remains of sesame seeds obtained from the Harappan civilization (circa 2000 BC). Seeds were first crushed in a mortar and pestle, and then boiled to extract the oil. At this time, oils were used for culinary purposes.

2,000 BCSoy oil produced

The Chinese and Japanese produced soy oil as early as 2000 B.C.

100 ADStone oil mill

Large stone mortars used as oilmills that date back to 100 AD to 200 AD were found in Dwaraka, Gujarat.

1750Roll mill

Roll mill invented by English engineer John Smeaton in 1750 to crush vegetable matter more efficiently.

1822Supercritical fluids discovered

The supercritical state of fluids was discovered by the French Baron Charles Cagniard de la Tour in 1822, although the true significance of his discovery and the possibilities it opened up only became apparent much later.

1855Carbon Disulfide used for Solvent Extraction of Oilseeds

Carbon disulfide was utilized as a solvent in the first solvent extraction. Since carbon disulfide usage involved a high risk of explosions, it was soon set aside.

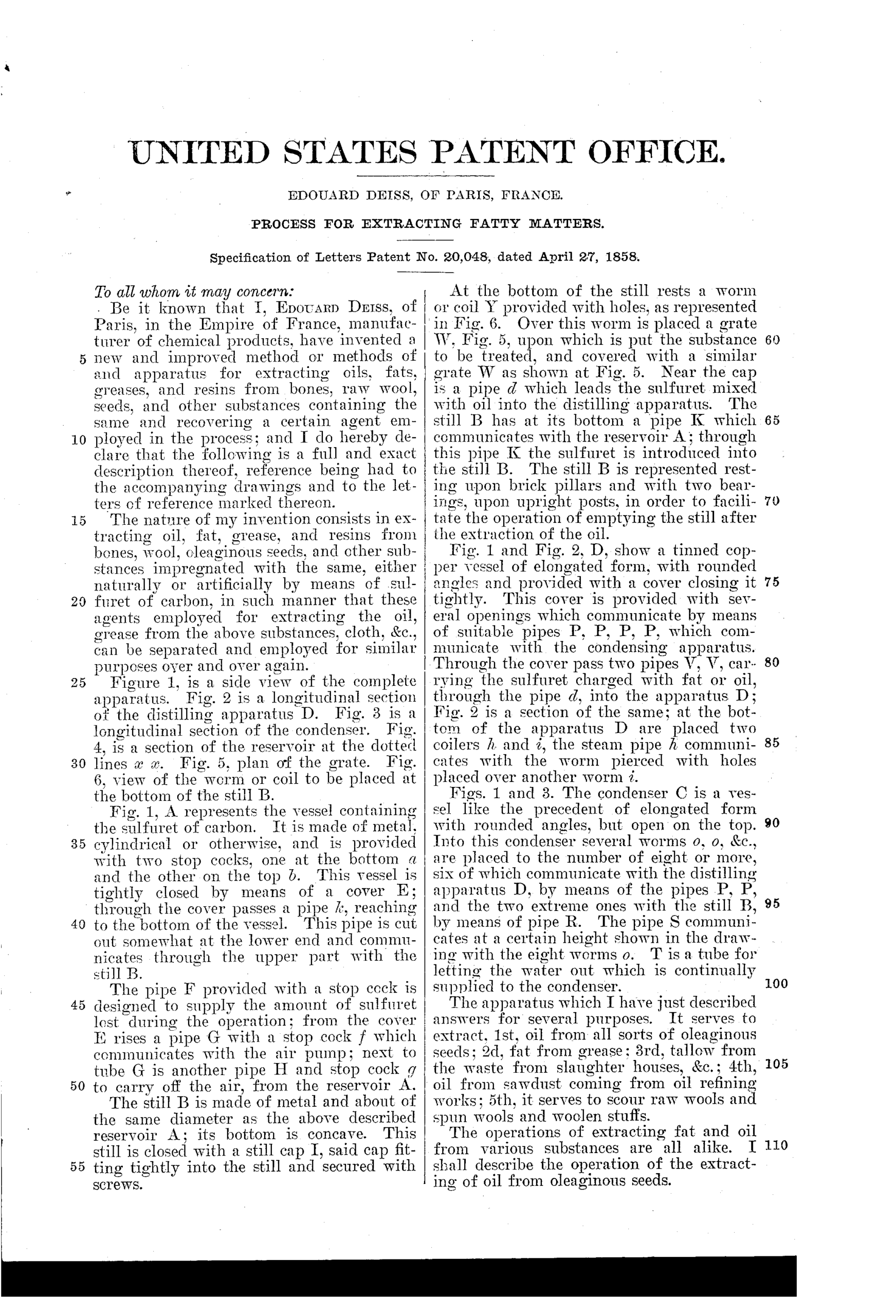

1856Solvent Extraction method was patented

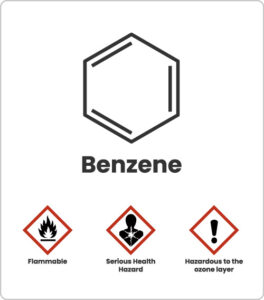

Deiss of England, following experiments by Jesse Fisher in 1843, obtained the first patent for extraction of oil using solvents, At first, solvents such as benzene were pumped through the material and drained through perforated false bottoms. Later, Bollman and Hildebrandt of Germany independently developed continuous systems that sprayed the material with solvent. Both methods were eventually improved, and today solvent extraction is the standard in the vegetable oil industry.

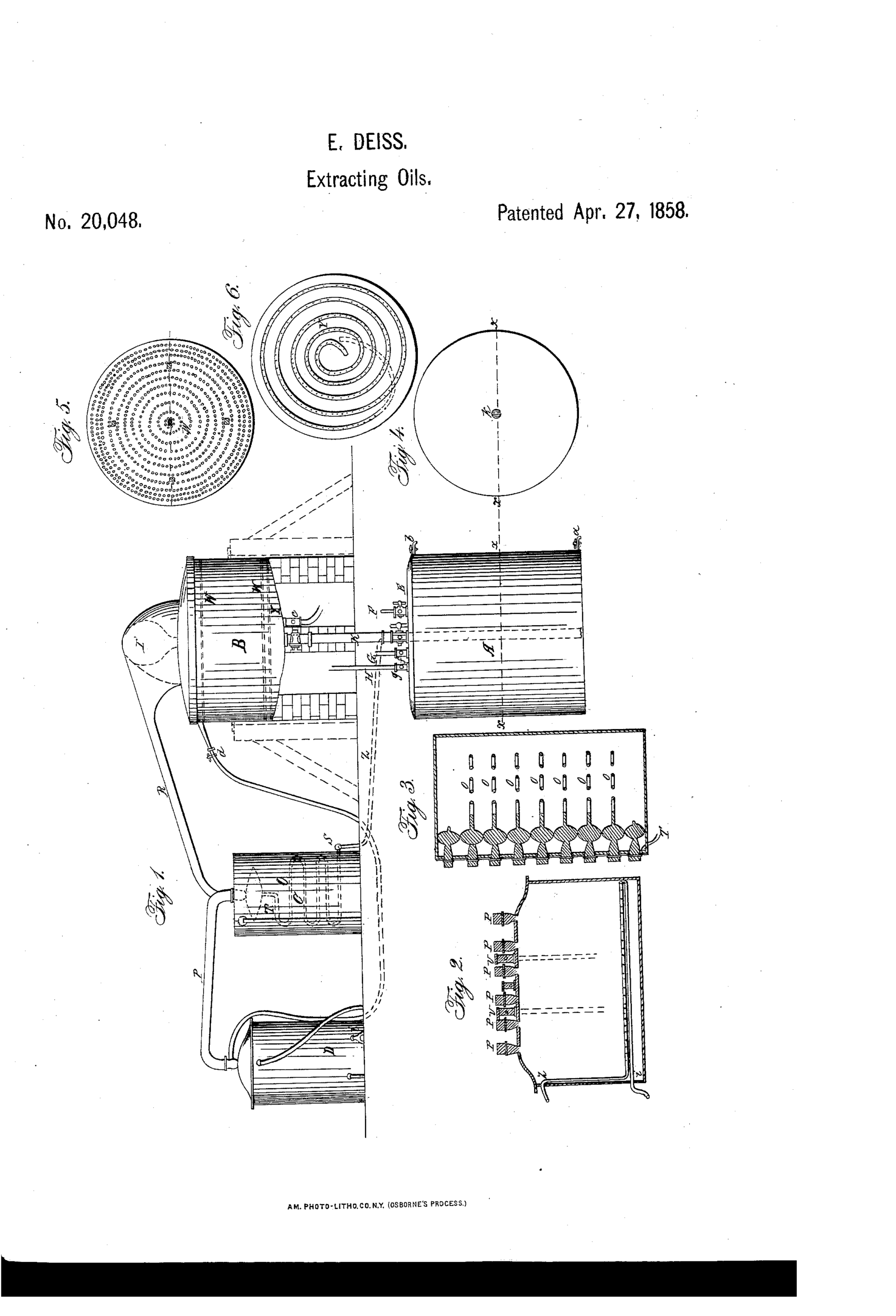

1876Screw press invented

The first improved screw press was invented by V. D. Anderson in the United States.

His “Expeller” (a trade name) continuously operated a cage press. Vegetable matter was placed in Anderson’s closed press andthe resultant oil drained out of slots in the side. A screw increased the pressure through the cage toward a restricted opening.

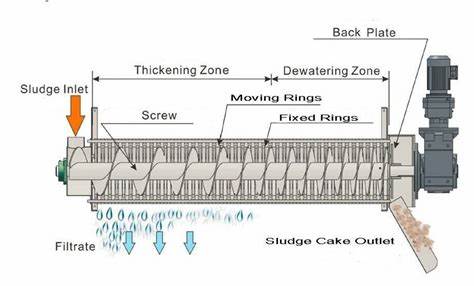

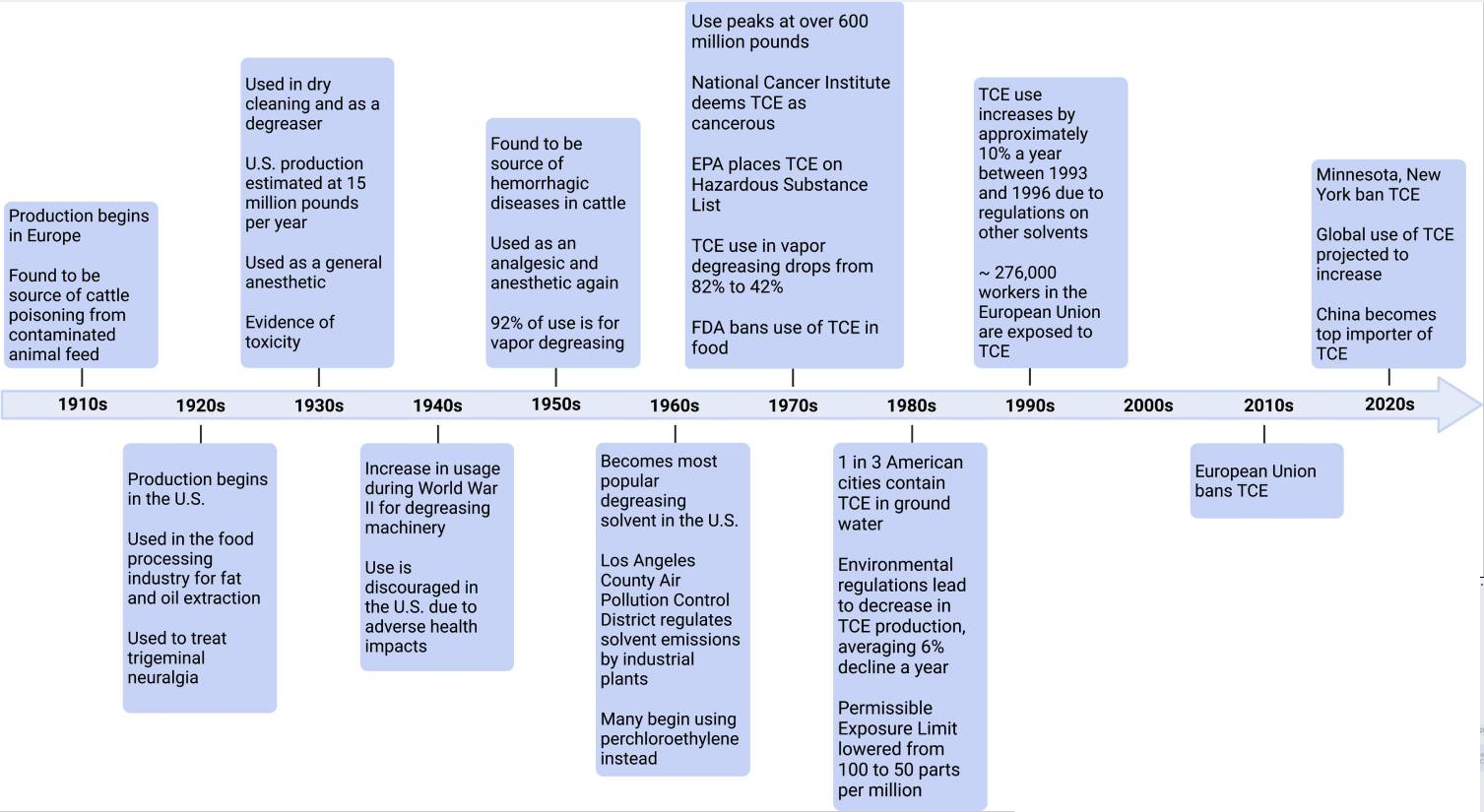

1912First uses of Trichloroethylene as an extraction solvent

The toxicity of trichloroethylene-extracted soybean oil meal (TESOM) is first observed by Stockman in Scotland. Trichloroethylene is a non-explosive solvent.

1914Soybean oil hardened by hydrogenation is first used in shortenings

In 1914, soybean oil is first used in margarine in small quantities.

In 1916, its use was increased to larger quantities in margarine.

1915-1917Use of benzene as extraction solvent

The South Manchuria Railway Co. constructs an experimental soybean solvent extraction mill (using benzine solvent) at Dairen, Manchuria.

1916More cases of cattle deaths due to trichloroethylene residues

Cases of poisoning in cattle by feeding with meal from soya bean after extraction of the oil in larger quantities.

The following link shows the earliest report seen of what later would be known as the Duren disease, and was found to be caused by soya bean meal extracted with trichlorethylene solvent.1920Trichloroethylene use for edible oil extraction increases

When trichloroethylene was first widely produced in the 1920s, its major use was to extract vegetable oils from plant materials such as soy, coconut, and palm.

1934Ordinary gasoline used as an extraction solvent

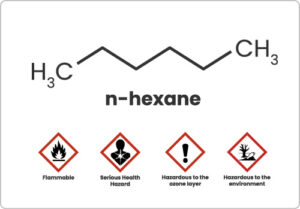

Before the 1940s, ordinary gasoline and other naphtas were used for oilseed extraction but odorous impurities gave the meal and oil a petrolike smell generating customer complaints. Hexane was developed from the same petroleum feedstock as a solvent free for imputiries, and therefore odor-free, offering better stability and extraction efficiency, though its price remains linked to gasoline markets. At that time, no toxicological studies were required to change the type of solvent used, before placing products on the market and ultimately on consumers’ plates.

1949-1950Hexane extraction as preferred method of oil extraction

Hexane extraction surpasses Expellers and screw presses as the most popular way of obtaining oil from soybeans in the USA.

1960First production of corn oil

1970Supercritical CO2 patented for the decaffeination of coffee

1977Trichloroethylene banned from use in Food products

The United States Food and Drug Administration (FDA, 1977) banned the use of trichloroethylene in food products because of its toxicity. Its use in cosmetic and drug products was also discontinued (Mertens, 1993).

2017N-hexane suppliers stopped the consumer applications of their product in Europe.

Challenged by the German Federal Office for Occupational Safety and Health (BAUA) on behalf of ECHA (The European Chemical Agency) on the safety of these applications, the n-hexane european suppliers decided to stop consumer applications of their product rather than provide further safety information or studies

2023United States EPA proposes Trichloroethylene Ban

In 2023, the United States United States Environmental Protection Agency (EPA) determined that trichloroethylene presents a risk of injury to human health in various uses, including during manufacturing, processing, mixing, recycling, vapor degreasing, as a lubricant, adhesive, sealant, cleaning product, and spray. The EPA proposed to ban the manufacture (including import), processing, and distribution in commerce of TCE for all uses except R&D.

202340 years to get rid of Trichloroethylene

Note that despite numerous studies showing how toxic trichloroethylene is, it took almost 40 years before this practice was discontinued.

Today, regulations will develop faster

It should also be noted that while it took regulartory authorities 40 years to finally ban trichloroethylene, due to the vastly improved information sharing via the internet and high speed data processing, regulators are expected to move much more rapidly to impose increasingly strict restrictions on the use of hexane as an extraction solvent.

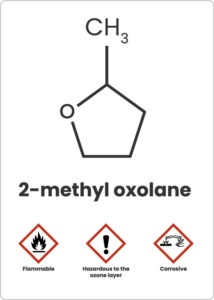

2023The EU approves a safe and sustainable replacement for hexane

After extensive toxicological, technical testing and a positive opinion by EFSA in 2022, 2-methyloxolane (2-MeOx), a plant-based solvent was added to the European list of approved food grade solvents.

2024European Food Safety Authority (EFSA) calls for a re-evaluation of Hexane use in food

On September 4, 2024 , the European Food Safety Authority concluded that there is a need for a re-evaluation of the safety of the use of technical hexane as an extraction solvent in the production of foodstuffs and food ingredients.

2025N-hexane enters the intention list of Substances of Very High Concern

Among the 22,500 chemicals available on the European market, 250 are classified as SVHC (substances of very high concern). These are the most toxic and widespread compounds that Europe aims to ban as a priority. n-Hexane is expected to be added soon to the list already including benzene, lead, PFOA, PFOS, bisphenol A, bisphenol S, trichloroethylene, and cadmium.