PATH TO HEXANE-FREE

With Four Key Services

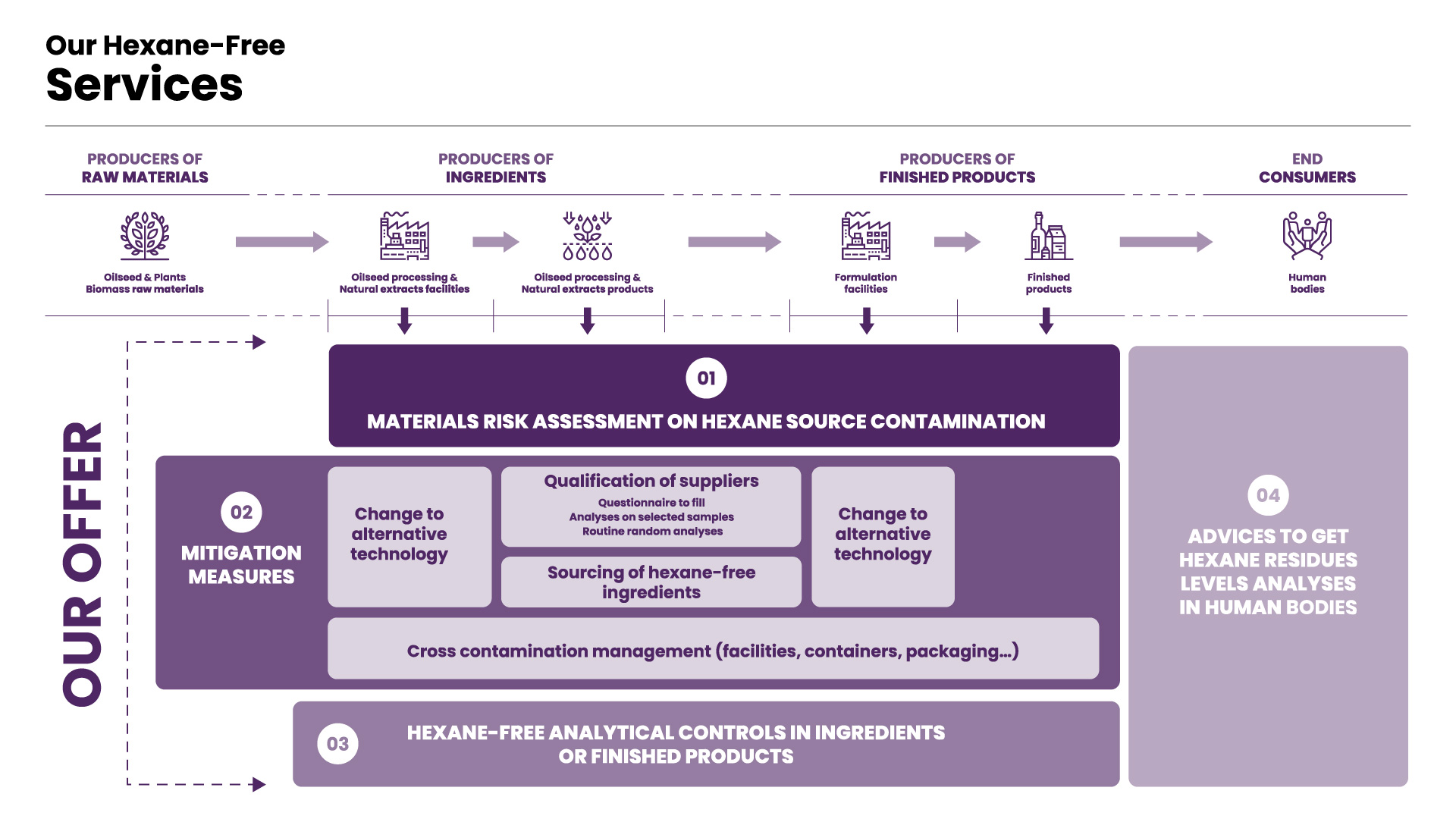

The transition to hexane-free processes is essential for industries involved in natural ingredient extraction, oilseed processing, and finished product manufacturing. A structured approach is required to assess and mitigate hexane contamination risks while ensuring compliance with industry standards.

Who Can Benefit?

These services are designed for all stakeholders in the supply chain:

- Producers of Raw Materials – Suppliers of oilseeds and other natural raw materials

- Producers of Ingredients – Manufacturers of natural extracts and ingredient products

- Producers of Finished Products – Companies formulating and packaging consumer goods

- End Consumers – Ensuring product safety and compliance

Key Services

A Step Toward Safer and More Sustainable Ingredients

The transition to hexane-free processes reflects the growing industry demand for safer and environmentally responsible ingredient sourcing. A structured approach combining risk assessment, mitigation measures, and analytical controls ensures a smooth transition while maintaining high product standards.

For companies exploring these solutions, tailored support can facilitate a successful and sustainable transition.